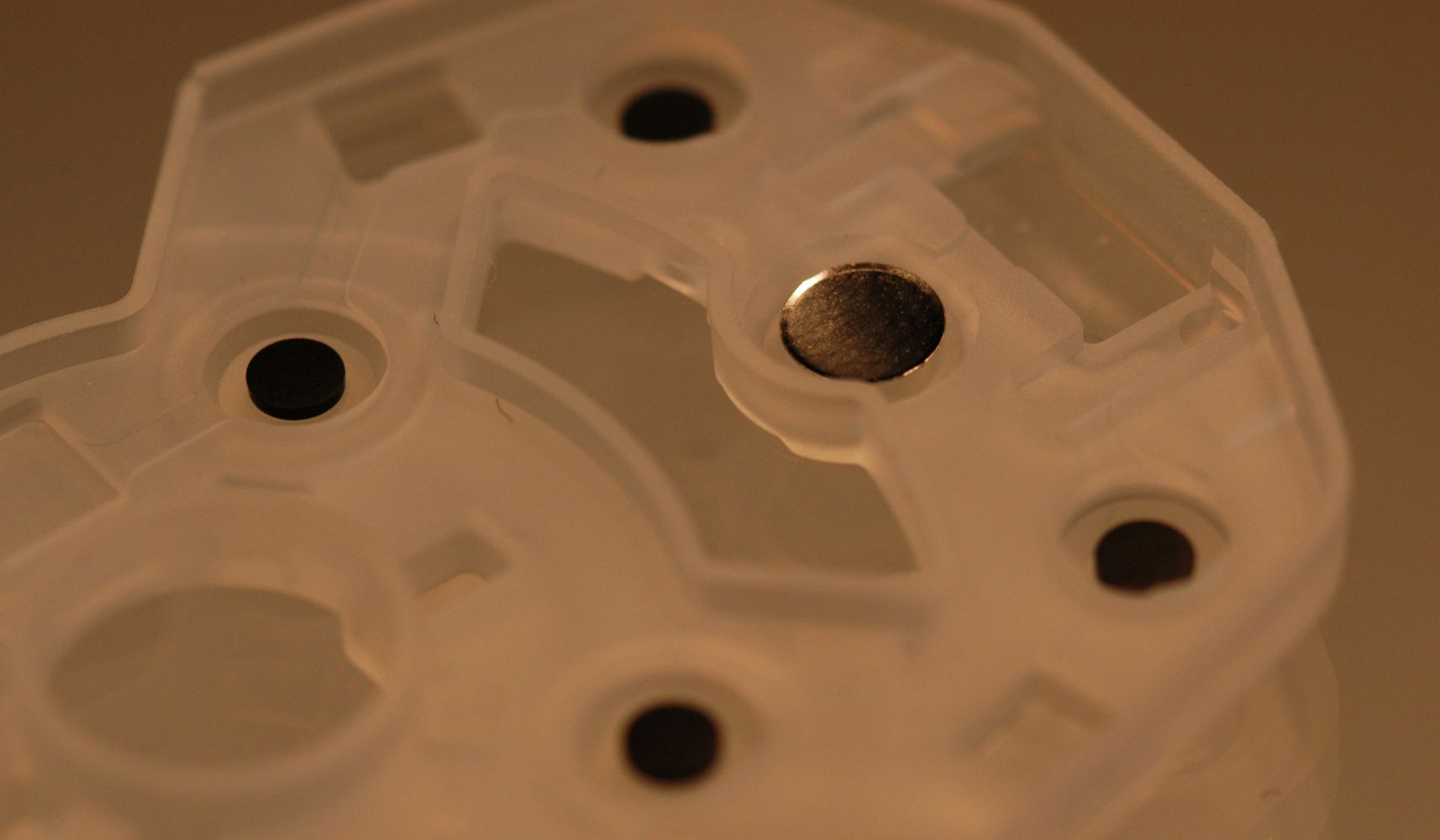

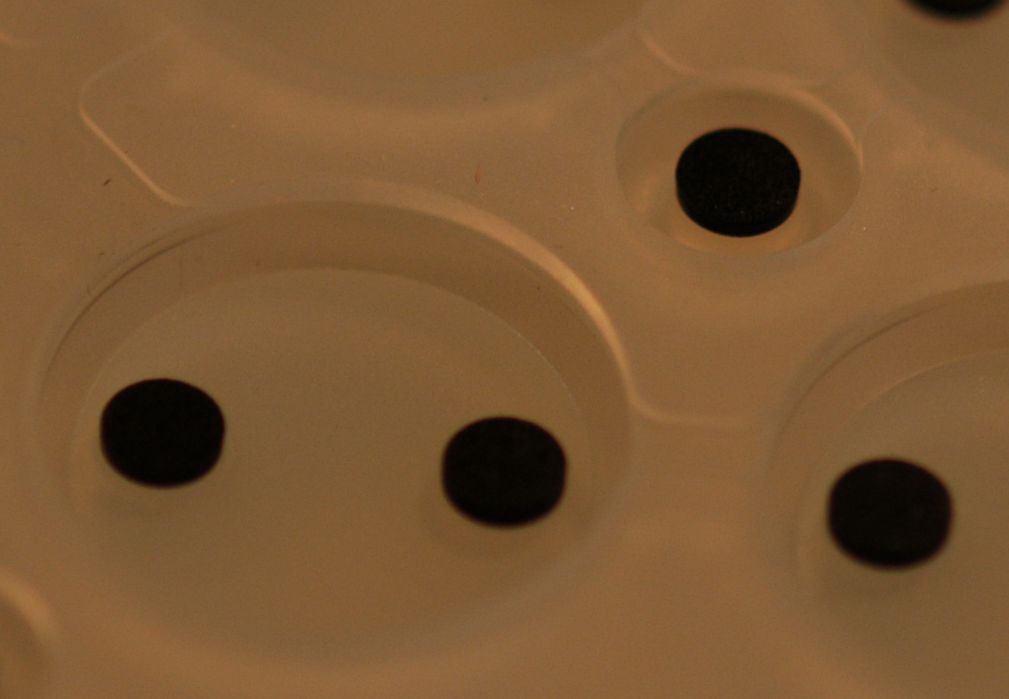

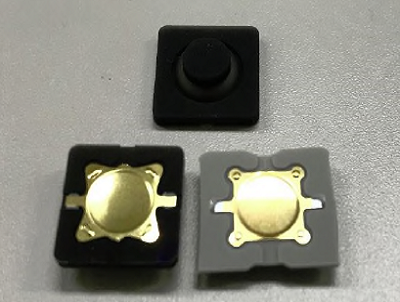

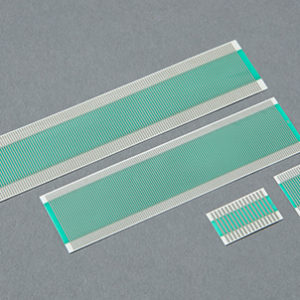

Part of the Shin-Etsu range of keypads is the contact element at the bottom section of each key that makes the actual electrical contact on the PCB or FPC. A range of materials are offered to meet various specific requirements towards switching electronic equipment. In addition to passive contact elements, metals domes are available that include a specific metal click-response.

Attaching metal domes to the keypad has the advantage that the pressure point is always centralized on the dome guaranteeing best click feeling by eliminating certain assembly tolerances.

Keypad contact element types

| Type | Conductive material | | Hardness | Tensile strength | Elongation | Compression set | Resistivity | Contact resistance | Size ∅ | T |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | Shore A | N/mm2 | % | % | Ω.cm | Ω | mm | mm | ||

| DCP | Direct Contact Print carbon silicone ink layer |  | (50) | (9) | (350) | (10) | 4.0 | < 200 20 typical | Various shapes 2.5 ~ 6.0 | > 0.03 |

| C40P | Carbon silicone rubber pill |  | 65 | 5 | 200 | 18 | 4.0 | < 200 20 typical | Round 2.5 ~ 5.0 | 0.55 |

| Alpha97 | Carbon silicone rubber pill |  | 80 | 6.7 | 160 | 36 | 0.7 | < 20 5 typical | Round 3.0, 3.5, 4.0 | 0.55 |

| Gold | Au plated Ni/Cu plate |  | (50) | (9) | (350) | (10) | 1.0 . 10^-2 | < 2 0.5 typical | Round 3.0, 3.5, 4.0 | 0.5 |

| H-flex | Au plated Ni/Cu plate |  | (50) | (9) | (350) | (10) | 1.0 . 10^-2 | < 2 0.5 typical | Round 3.0 | 0.55 |

| JIS K6301A | JIS K6301 | JIS K6301 | JIS C2123 150 °C, 22hrs | |||||||

| Test based on Shin-Etsu standard test on Au plated PCB, 1.0 pitch, track width 0.5 mm. |  | |||||||||

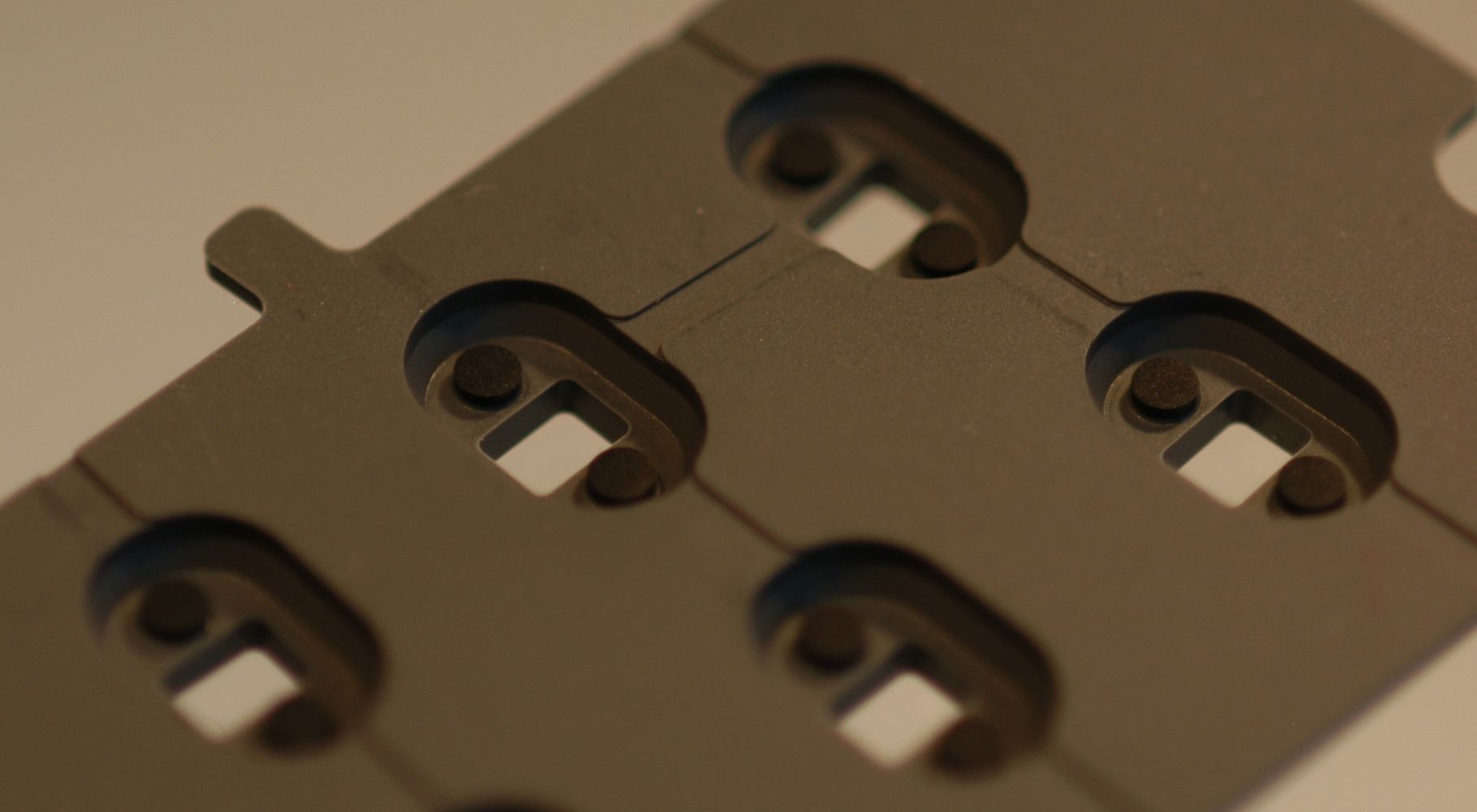

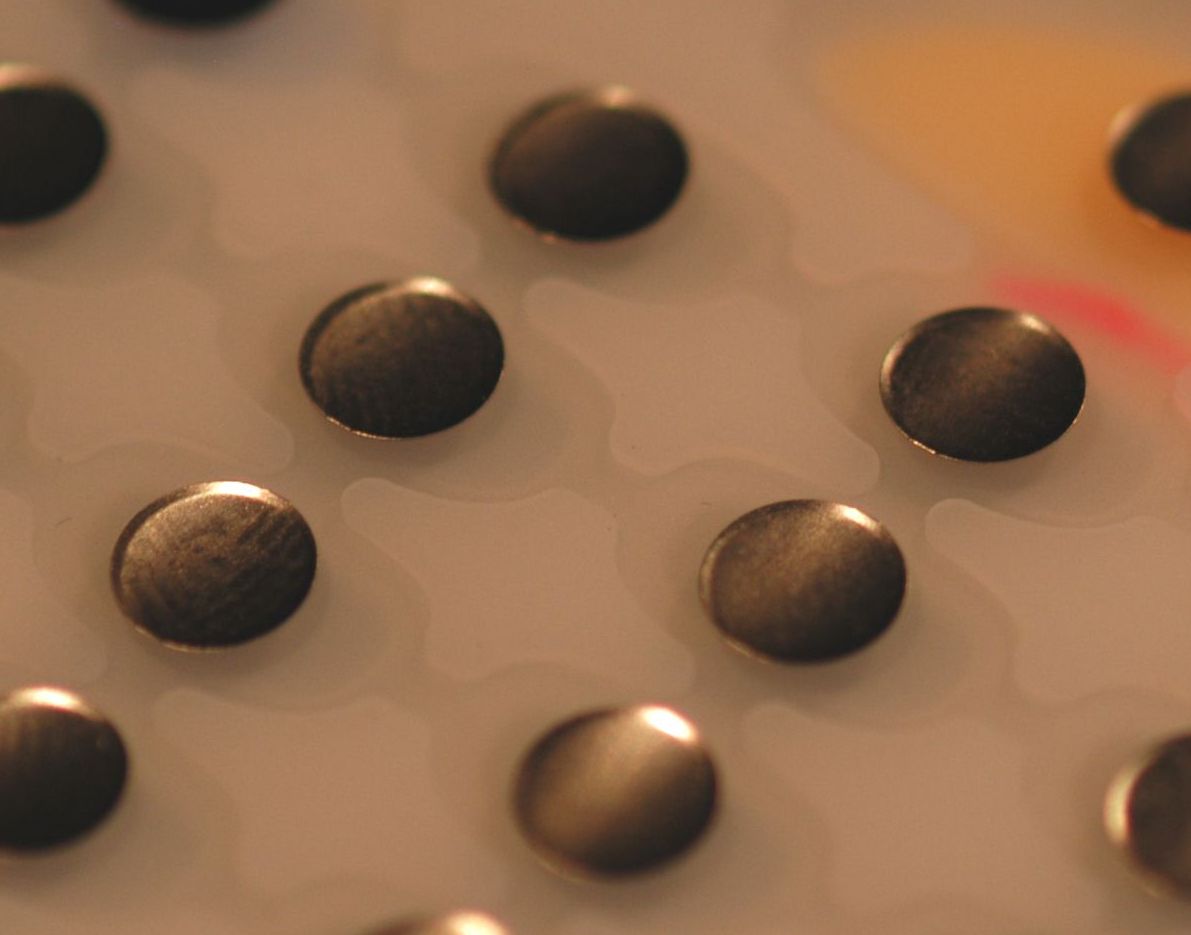

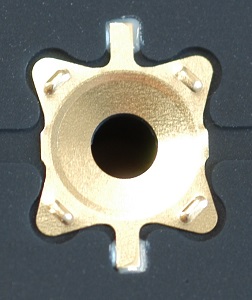

Keypad metal domes contact element types

| Type | Conductive material | | Size ∅ | Contact resistance | Peak force | Stroke | Click ratio |

|---|---|---|---|---|---|---|---|

| Unit | mm | Ω | N | mm | % | ||

| MD | SUS | < 50 | 0.8 ~ 8 | 0.8 ~ 1.5 | 0 ~ 70 | ||

| IF | SUS301CSP-H |  | 4.0 | < 50 | 1.8 ± 0.4 | 0.14 ± 0.05 | 45 ± 10 |

| IF | SUS301CSP-H | 5.0 | < 50 | 1.8 ± 0.4 | 0.18 ± 0.05 | 45 ± 10 | |

| IF | SUS301CSP-EH | 5.5 | < 50 | 3.8 ± 0.5 | 0.23 ± 0.05 | 40 ± 10 | |

| IF | SUS301CSP-EH + carbon coating | 5.5 | < 100 | 3.9 ± 0.5 | 0.24 ± 0.05 | 40 +10/-15 |